A while back I got asked by my woodworking magazine editor if I fancied doing an article on making a different door handle.

I have a weird aversion to making or fitting handles. I'm not sure why, I just don't like them very much. So I saw this as a good challenge.

I had a rough idea of what I wanted to make, I didn't want it to be turned and I wanted it to work with some wardrobes I'd made a few years back. I had some beautiful wood from an old door I fancied using as well.

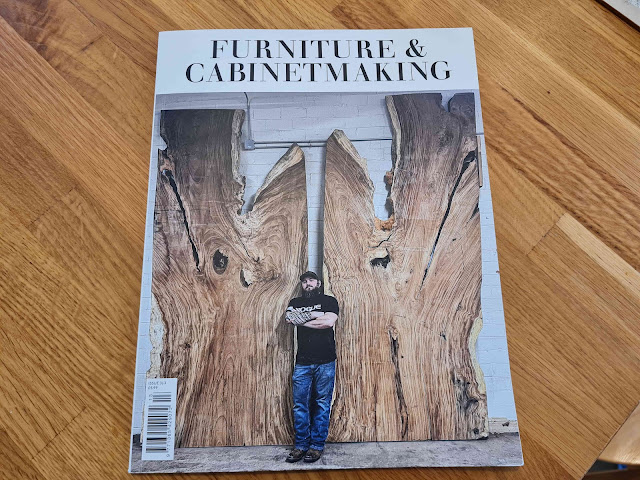

A fun piece to make and nice to be back in F&C magazine as it's not one of my regular ones. This project was made in May - to give an idea of how things turn in the magazine world.

What's your favourite style of door knob or pull?

Would you have these fitted to anything in your house?

I guess since the "crown guard" is a European invention, that is why we call it a riving knife. I'm not sure where mine is these days. It got bent at one point and then never tracked really well with the blade and caused problems. Since my saw is underpowered, kickback isn't an issue anyway on wood long enough to bind. It just stalls until I shut it off.

ReplyDeleteI like those drawer pulls and would definitely use something similar if needed. I have stripped down enough kitchens over the years, that I just raid the drawer for leftover pulls when necessary. Only recently did I make some out of leftover scrap for the cabin project but they weren't as nice as yours.

We call the bit behind the blade the riving knife, this stops the wood binding on the blade (in theory) and then the crown guard goes on top, sometimes joined to the riving knife, sometimes supported from above. My saw would probably stall as well, it's not incredible (just a dewalt site saw) but I've worked with some big old wadkin machines (especially at college) where they could kick back and take out a window. I've got into bad habits using weak saws and often push with my belly which is a big no no really!

DeleteAs for the handles, it s a job I always leave. My carved wooden work bench every one tells me is lovely then they ask why I have screws for handles! I wanted some walnut to turn some little pulls, but have just to get any.

Looks really good Kev! It is a funny thing looking at yours; handles are not really something I pay attention to that much - in fact, I think the cabinets in our kitchen do not have them at all. I am not sure if that is an American thing or just a building era thing.

ReplyDelete